So what does this mean in the real world?

The following unique properties.

- Plastics that are 10x stronger than metal

- Materials that weigh 50% less

- Anti-Bacterial & UV protect surfaces

- Improved tensile strength and stress resistance properties

- Thinner applications and fillers

- Thermal & Audio insulation barriers

- Magnetic & Optical properties

- Electrical insulation barriers

- Reduced material usage

- Reduced manufacturing costs

- Reduction in CO2 emissions

In essence, a cleaner, light, stronger, eco friendly product..

The move towords high performance materials and environmentally resposable manufacturing is driving a wave of new innovation in plastics and metals.

New Nano Composites can provide the answer to...

- Weight Reduction

- Strength

- Reinforcement

- Conductivity

- Barrier Properties

- Anti-Bacterial Surfaces

- UV Resistance

Nano Composites are produced by dispersing nanometer sized particles in a matrix.

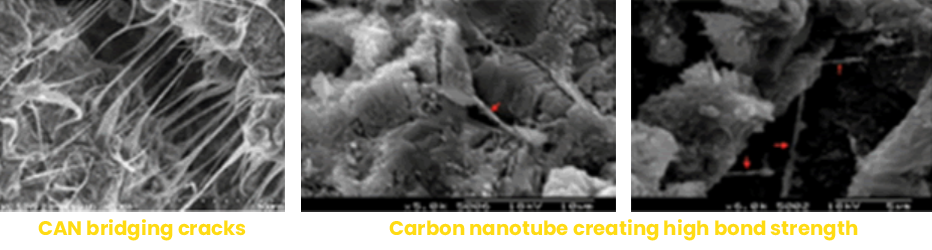

A matrix with a multi-walled carbon nano tube providing increased flexural strength, compressive strength and reduction in failure strain.

Diagram 1 Interfacial interaction between CNT and matrix products high bonding strength between reinforcement allowing for less material usage

Diagram 2 & 3 Carbon nanotube creating high bond strength Carbon nano tubes bridge accross voids and cracks which helps in load transfer in se of any teension.

Addition of CNT and other nano-particulates to resin improve its durability through phycal and chemical interactions such as pore filling and pore size distribution.